How to Check If Your Bike Chain is Worn Out

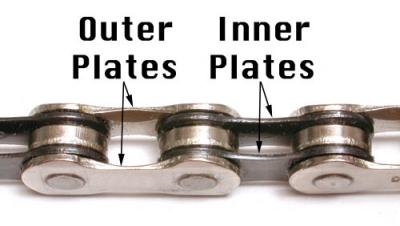

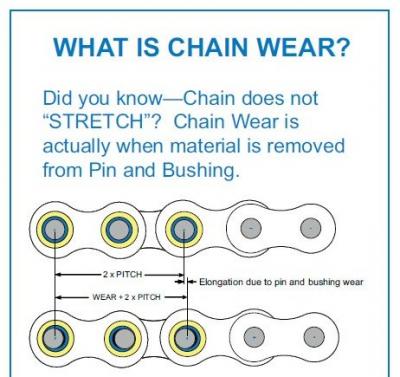

Chain wear can definitely affect your ride for the worst and can cause an accident. They wear out as a result of the rivets being pulled on by the outer plates. It’s what they call a chain stretch. The chain itself doesn’t really stretch; it’s just the plates being pulled apart.

At any rate, it’s no good so to check if there is wear. If things don’t look perfectly round or straight, that is a possible indication of damage.

Your chain is really far gone if, because they stretched and pulled so much, they don’t even sit on the sprocket teeth and ride up.

There are also a couple of methods you can use to check. One is using a chain checking tool like this one:

Stick it in the chain, curved side first. If the other side fits into a space on the chain, that is an indication that you will need to replace the chain. The numbers read right-side up indicate two different things: .75 indicates that it’s time to buy a new chain; 1.0 indicates that you’ll probably have to buy new sprockets and a chainring as well.

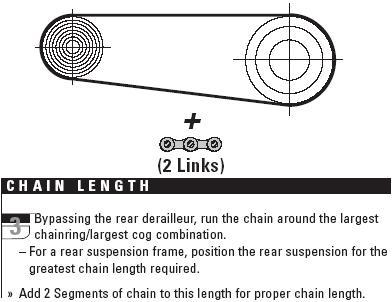

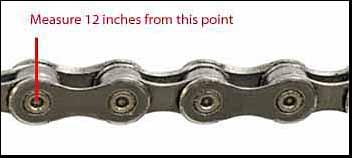

If you don’t want to shell out for a tool, you can go old school and measure. Take your chain and starting from a pinhole, measure off 12 inches of the chain. The 12 inches should hit the 12th link’s first pinhole. If it goes over by 1/16” past the mark, you’ve got to buy a new chain. If it is 1/8” past the mark, you will need to buy a new chain, freewheel and chain ring.

You’ve got to remember that if there is bad wear in the chain, it has probably screwed up your cogs and chainrings as well, wearing them down.