How To Paint a Bicycle Frame

While your bike frame performs mainly a functional purpose of holding all the components together and yourself upright, that doesn't mean it can't be stylish at the same time. Whether you're salvaging an old bike frame that rusted away in a storage shed for 9 years or just want to add some new pizazz to your current arrangement painting a bike frame is relatively simple. Follow these tips to make your sparkling new frame the envy of the road, the trail, or the cul-de-sac.

The finished product is going to look pretty sick...but there's work to do first

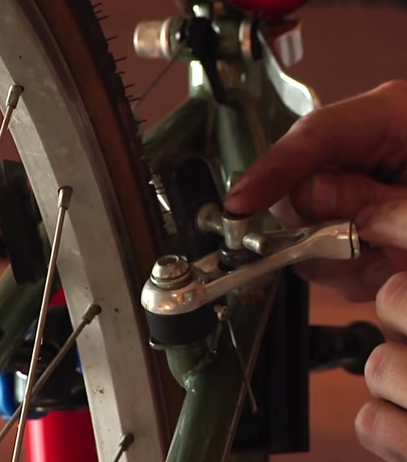

Prep the Bike For Paint

Before you can repaint your frame in a new color, you need to get rid of the old shade first. The first few things you need to remove the old paint are rubber gloves, a paintbrush, and something called aircraft paint stripper. Dip you paint brush into the stripper and brush it onto the bike frame as if you were painting it. The material chemically reacts with the paint so you'll want to let it set and do its job. Once a good majority of the paint has flaked (it won't get it all) apply water to the frame to stop the reaction. After applying the aircraft stripper, the next stop is to sand down the frame with sandpaper or scotch brite. You need to spend a long time in the sanding process because the smoother the frame the easier it is to apply the new coat. Start with a low number rough grade paper and work your way up to the finer material. Once you've completed sanding, wipe down the frame with a wax and grease remover but don't touch the frame with your fingers because oils will show through on the final coat. Alas, you're ready to paint.

The aircraft stripper works pretty good but make sure not to let it sit too long or it'll eat your whole bike.

Applying The Paint

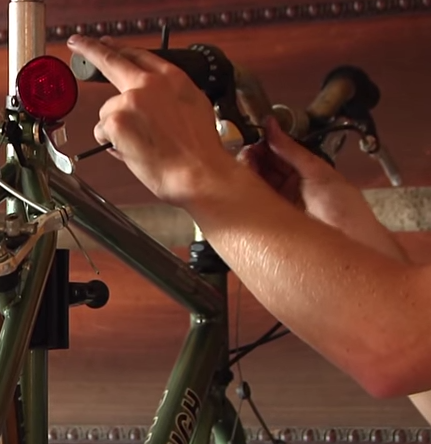

After your sanding and prep work is done, use masking tape to block off the areas of the bike you don't want painted such as the internal opening of a seat post or stem. You'll need primer, 1000 grit sandpaper, the color of paint you want to use, clear coat, rags, scotch brite, and grease remover. You can also use either a sprayer or a rattle can. The first step after prep and marking off is applying the primer. It generally works better to do multiple light coats instead of one heavy one. Cover the entire bike and let it dry accordingly. Next take the 100 grit sandpaper and make sure the frame is smooth before applying one last coat of primer. Next apply the paint just as you did the primer, by taking your time and doing light coats. Let the paint dry and if you have any decals install them now before applying a clear-coat finish. Finally apply 2-3 layers of clear coat and you've got a brand spanking new looking frame in less than a day.

Some people lose motivation at the primer stage. You've no doubt got a dude in your neighborhood that drives a 'primer gray' 1985 Mustang

Next put the bike back together and get out and ride!