How to Install a Star Nut in a Bicycle Fork

I'm going to show you how to install a star nut into your bicycle fork.

Star Nut in Fork

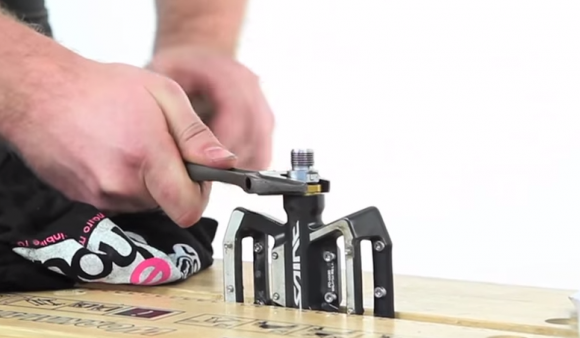

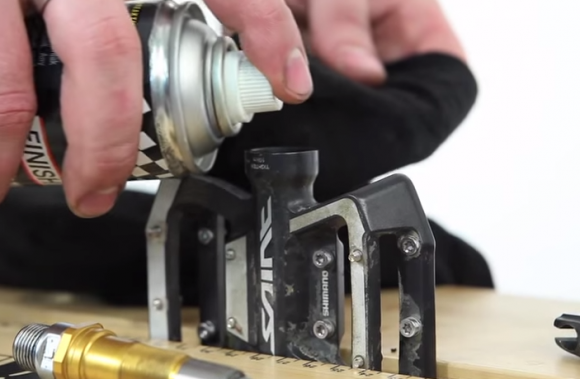

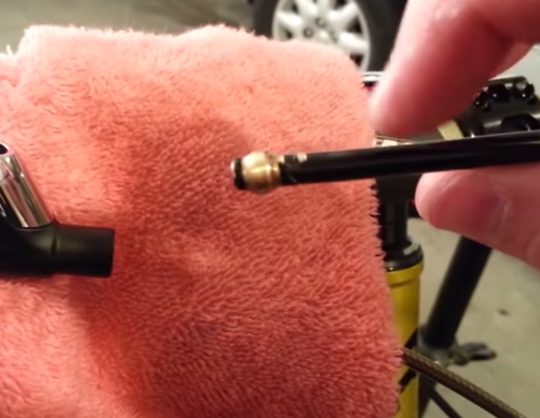

In order to install the star nut straight into the steer tube of the fork, you need a tool. This particular one is for 1 1/8 inch steer tube and it attaches to the star nut, which is going to go into the fork. This allows you to thread the star nut on to the bottom, set it on to the fork, and then it will hold it straight while you hit it with a hammer.

Tool Used to Set Star Nut

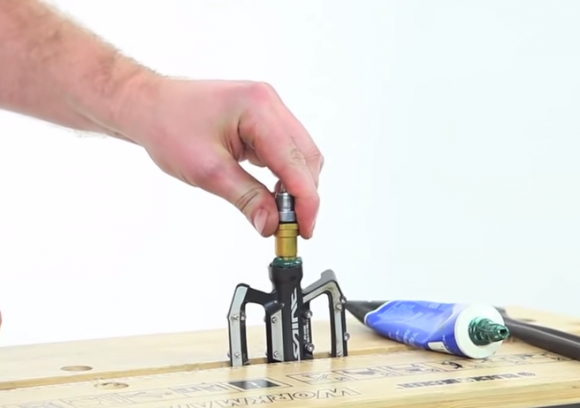

The first thing is to thread the star nut on to the bottom of the installation tool. Make sure it threads on all the way and then this goes right on top of the fork. Now it's already set to set it at the right depth and also to the the size of the steer tube. It's going to go on here, and then this coller sets right over the top. Once you're done hitting it all the way in, you'll hear the tone change when it starts to make contact with the steer tube. You can take the top part of the tool and unscrew it from the star nut that is now inside the steer tube. The top comes off. Your star nut is now installed.

Unscrew Tool from Set Star Nut

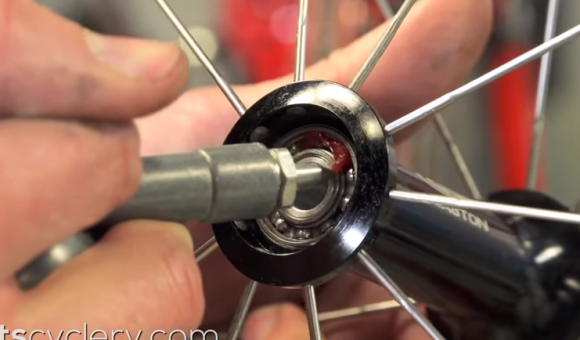

So now once the star nut is installed, you can reassemble the fork into the bicycle with the headset, and having the star nut properly installed will allow the bearings of the headset to fit tight together, the stem to fit on top, and everything to compress and give you smooth steering. That's how you install a star nut in a bicycle fork.