Ian wants to know: the bearings in my Roval wheel feel rough when I spin them around. How do I replace the bearings or overhaul my hub?

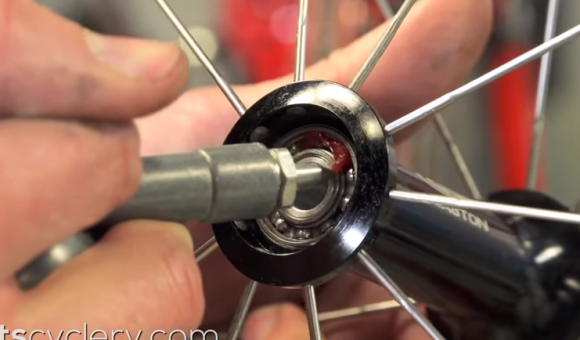

The quick way to overhaul cartridge bearings is to work on them while they are in the hub. Start by removing either the axle or axle end caps to expose the bearings. On the rear hub, you will need to remove the freehub body as well. Use a knife to pry up the seal on the cartridge bearing.

Use a Knife to Remove Cartridge Bearing Seal

Use a rag to mop up as much of the grease as possible by turning the bearing or the wheel as you wipe down the bearings, then spray the bearing with degreaser to loosen up the remaining grease. Repeat the process as many times as needed to get all the gunk out.

Spray the Bearing with Degreaser to Clean

A quick spurt of WD-40 will get the water and the degreaser out of the bearing. Then use a rag to remove as much of the WD-40 as you can. Now repack the bearing with high quality, uncontaminated grease. If you live in a wet area pack a lot of grease to protect your bearings. For everyone else, a light coat will reduce bearing drag, while still offering proper lubrication.

Repack Clean Bearing with Grease

When it comes time to replace the bearings every hubs a little different. For hubs like this one from Easton, the axle has internal shoulders that require one bearing in the axle to be removed at the same time. To do this tap on the end of the axle with a soft faced hammer to push the assembly out of the hub. You can get by using a punch to remove the bearing, but if you aren't careful this can damage your hub. You also risk the possibility of punching out just the inner bearing race and leaving the outer race still inside the hub. For bearings that are removed independent of the axle, a bearing puller, like this one from Enduro, is the right tool for the job. To use the bearing puller insert the collet end into the bearing and expand the collet.

Insert Collet End of Bearing Puller into the Bearing

Thread in the slide hammer and then use it to pull out the bearing. To install the bearings correctly, use a drift that is made to press on the outer race of the bearing, or both the inner and outer race of the bearing. If your drift only presses on the inner race of the bearing, it can damage the bearing upon installation. Your drift should be driven by a threaded press rather than pounded in with a hammer for best results. While you can make your own threaded press with an old skewer or threaded axle, a press that is made to fit the inner diameter of your drift will keep the bearing going in straight, thereby avoiding damage to the bearing and hub. Reassemble the axle and caps, and free hub body, and you're all done.