Bike Crankset

Crankset Fixes, Reviews & Guides

How to Overhaul Your Bottom Bracket

One of the ways you can keep your bike riding smoothly is by giving it a good cleaning, both inside and out. Overhauling a bottom bracket will most likely not be in your weekly cleaning regimen...

Company: Park

Type: Repair Tutorial

How to Install a Bottom Bracket

I like being thorough and bike mechanics requires a lot of attention to detail. If you don’t get it right the first time, your ride suffers. And the level of competence, time and patience can...

Type: Repair Tutorial

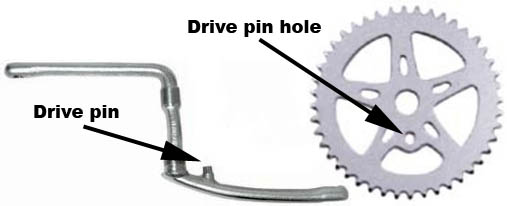

How to Remove a Bicycle Crank

If you have the right tools removing your crank is a relatively simple and painless process. In this video we removed a square taper crank, also know as a cotterless crankset. These days there...

Type: Repair Tutorial