In this video, we're going to show you how to fit a Campagnolo over torque bottom bracket and change set. The over torque bottom bracket is a standard BB 30 press fit. To do this job, you'll need a bearing press with Campagnolo over torque adapters, Campagnolo over torque bottom bracket tool, a number of allen keys, and an adjustable or 24 millimeter spanner. You'll also need some grease for general assembly.

Start by putting the retaining clips into the frame. It should be obvious when these have clicked into place. Once the clips are in place, it's time to put the bearings in. The bearings need to be parallel when they go into the frame so that they are not damaged by the bearing press. Position your bearings carefully by hand and check that they are straight. Put the over torque adapters on to your bearing press and make sure the discs are directly in line with the bearings. Start using the bearing press to ensure that the bearings are not going in at an angle. One bearing may go in to place first, but the other one should soon follow.

Put Bearings into Place with Bearing Press

With the bearings in place, it's time to put the cracks on. Make sure that you grease the seal and then push the cranks through the bottom bracket. Put the seal and spacer on the left hand side of the axle, making sure to also grease the seal on this side. Before you put the left crank on, put the expanding sleeve on the axle. This sleeve has 3 teeth, and they should all be facing outwards.

Put Sleeve with 3 Teeth on Cranks

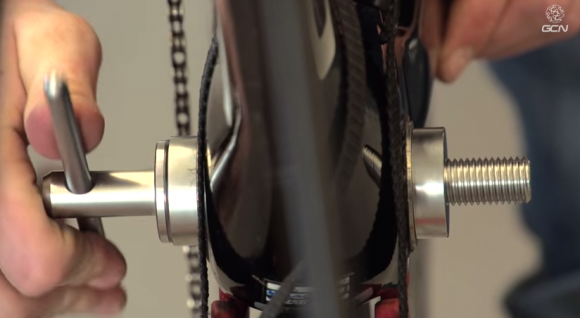

With the sleeve in place, put the non drive side crank arm on, and make sure that it is correctly lined up. Put the lock ring on with the first part of the Campagnolo over torque bottom bracket tool. Use a 5 mm allen key to attach the tool to the bottom bracket axle, Then use to an adjustable or 24 mm spanner to push the crank onto the axle.

Put Lock Ring on with Bottom Bracket Tool

Like us, you might reach a point where the tool won't go any further, but there's still some play in the bottom bracket. At this stage, remove the over torque bottom bracket tool, and use the adjustable sleeve on the non-drive side to take up any remaining play. To do this, spin the adjustable sleeve around the axle until it has taken up all the slack, and then use a 1.5 mm allen key to tighten this up. It's always worth checking your work, so test for any play on the bike stand and on the ground.