Fix Noisy Road Cycling Shoes with Cleats

Cleat squeaks can come from a number of different sources such as the cleat to shoe interface, the cleat to pedal interface, or from the binding mechanism housed in either the pedal or cleat. We'll address these issues one at a time. With the quick lessons shown in this video, noisy cleats will be a thing of the past. Don't forget to explore the rest of our Learning Center for more great instructional videos. Once your bike is all set up, make sure none of your components will hold you back. Check out our wide selection of bicycle components over at ArtsCyclery.com.

Step 1: Tighten down the cleat to the manufacturer's recommended torque value to limit cleat flex and the creaking it generates.

Tighten Cleat

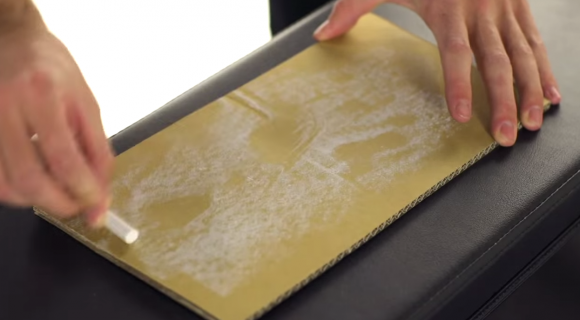

Step 2: Greasing cleat bolt threads and underneath the bolt head can also help to quiet down flexing cleats.

Step 3: If you use Speedplay pedals, make sure that your cleats are properly shimmed so that they do not become warped when they are tightened down, as this is a common source of creaks.

Step 4: At the cleat to pedal interface, most creaks are the result of worn out cleats that rock on the pedal body. If the colored wear areas on your cleats are worn down, it's a good time to replace them.

Step 5: Lubricate the contact points where the cleat and pedal meet with a dry chain lube. Rock ÔN Roll Absolute Dry chain lube is a good example of the type of lube you want to use. Just keep in mind that a little goes a long way and that you need to wait for the solvents to evaporate before you ride in order for the lube to remain in place.

Grease Cleat Threads

Step 6: Follow this same procedure on your cleats if you use Speedplay pedals. Clean out the spring/cleat interface and then lubricate it with a dry lube.